Rotary Oven in Kenya (330 loaves per hour) – 32 trays

/= 3,910,000.00 Original price was: /= 3,910,000.00./= 3,300,000.00Current price is: /= 3,300,000.00.

- It is made using high quality stainless steel on the exterior and interior sections of the oven.

- It has a double – layer tempered glass on the oven door for ease of viewing.

- It can bake approximately 165 loaves/batch (330 loaves/hr of 400gms).

- It is dual powered oven giving two power options when baking.

- It has a 1 year warranty.

- It is also CE certified.

Product Description

Introducing Dual Rotary Rotary ovens in Kenya.

If you are planning for large commercial scale of baking either breads, buns, scones, rolls, cakes and cookies you must consider the Rotary Oven. This oven is also referred to as the Rack oven or simply as Rotary Rack oven.

There are 3 main type of commercial ovens namely deck ovens, convection ovens and rotary ovens. Before deciding on which one to go for, its important to consider the different baking oven prices with different capabilities and production output.

What is the definition of a rotary oven:

It is a heavy duty stainless steel oven with baking surface ranging between 2.8m2 to 9.6m2, this depends with the oven size. There are 3 main sizes, 16 tray, 32 tray (both single rack/trolley) and 64 tray (double rack/trolley). They weigh 1,500, 2,000 and 2,500 kilos respectively. They consist of a rotating trolley inside also referred to as a rack. They are composed of two chambers, burning chamber and baking chamber. Burning chamber is made of heat resistive steel and burns gas, diesel or electricity converting it to high pressure heat channeling it to the baking chamber.

Due to rise in diesel costs that have affected commercial baking, Bakewave has now introduced a new series of Rotary ovens known as Dual Rotary ovens. These include Dual Diesel Rotary Ovens and Dual Gas Rotary Ovens.

Past Rotary Oven Limited Fuel options

Prevoiusly, Rotary ovens were powered by:

- Either 100% electricity.

- A hybrid of diesel 95% with electricity, but not in the same oven.

- Also gas hybrid 95% with less electricity about 3KW was available.This fuel options could only work in a particular rotary oven designed only for a single fuel option.

That means if you were using a diesel hybrid and needed to switch to solar or electricity, it was impossible. It also meant that if you ran out of diesel (incase of diesel rotary oven) or gas fuel (incase of gas rotary oven), there was no way you could save your bread in the oven.

In Africa, the diesel hybrid (95% diesel) is common with baking taking place from a diesel source and about 3KW electric power is required for rotation and control panel operations. Many times we have had instances where customers forget to refill the diesel tank (which is mostly located outside)and which ends of in loss of bread product in the oven ,proofer or in the mixing process.

THE NEW DUAL ROTARY OVEN FUEL OPTIONS:

The new Bakewave Rotary ovens come in 2 options;

- Dual Diesel Rotary Oven.

- Dual Gas Rotary Oven.

1. DUAL DIESEL ROTARY OVEN

For the dual diesel rotary oven, oven bakers have the following fuel options at any time:

1. The usual diesel (95%-baking purposes) combined with about 5% electrical power (2.6kw for control panel, fuel ignition and rotation purposes).

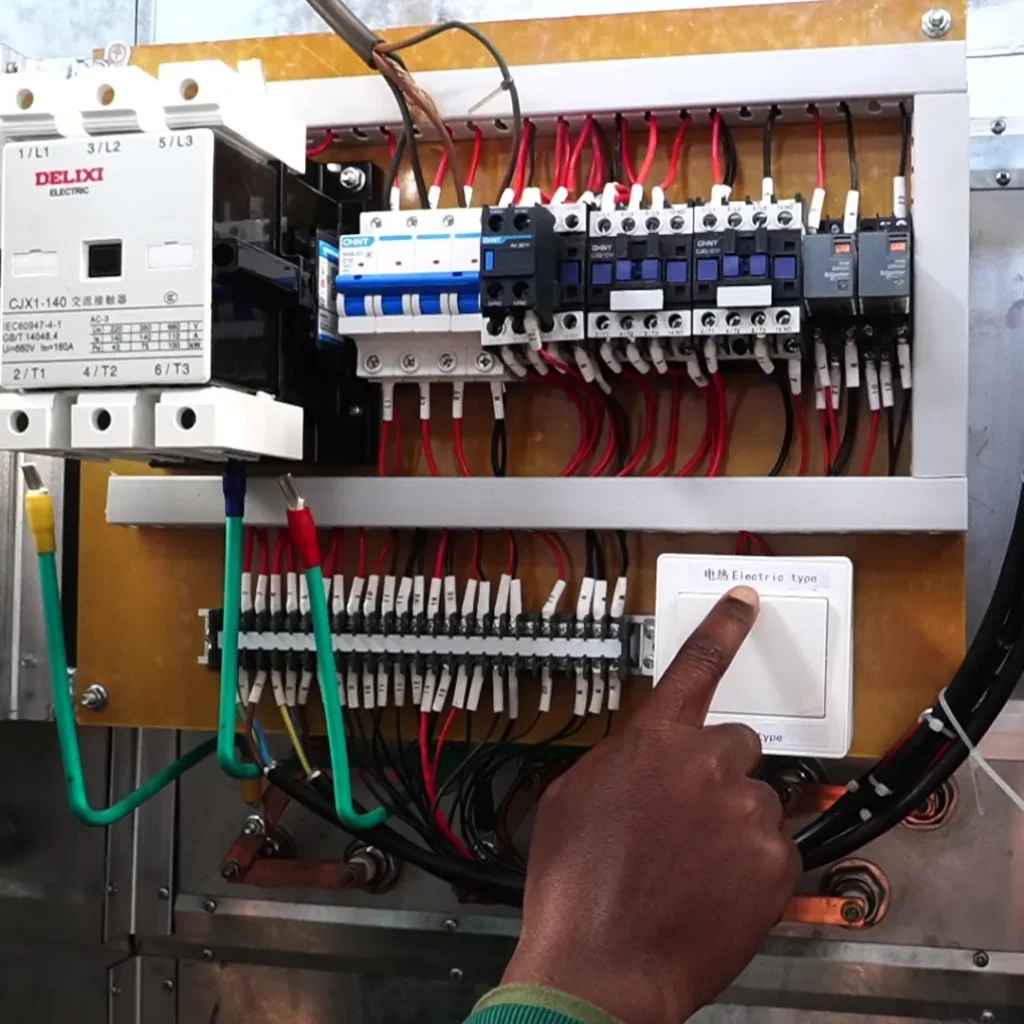

2. They can flip a switch(check video below)and switch to 100% electricity. Incase diesel depletes without warning or incase power tariff charges are low(it could happen at night in Kenya when government offer lower electricity tariffs as incentives).

3.Because oven is 100% electric it can therefore use 100% solar. This is very important in future as companies prepare to go green and lower their energy costs.

The Dual Rotary Oven Switch

2. DUAL GAS ROTARY OVEN

1. The usual LPG gas (95%-baking purposes) combined with about 5% electrical power(2.6kw for control panel, fuel ignition and rotation purposes).

2. They can flip a switch(check video below)and switch to 100% electricity. Incase LPG gas depletes without warning or incase power tariff charges are low(it could happen at night in Kenya when government offer lower electricity tariffs as incentives).

3. Because oven is 100% electric it can therefore use 100% solar. This is very important in future as companies prepare to go green and lower their energy costs.

4. Biogas – This oven can use natural gas such as biogas. In the past, Bakewave has set up many large bakeries which have dairy farms. These bakeries can utilize the biogas they produce(95% for baking) with only 2.6Kw of electrical power needed for rotation of the oven and lighting up the control panel.

What is the difference between rotary oven and convection oven?

- Rotary oven is bigger and recommended for above 2,000 loaves production daily. A convection oven is smaller and is recommended for less than 2,000 packets of either bread, buns, rolls or cakes. Rotary ovens are recommended for production of 2,000 packets of buns or scones or etc in a day.

- Rotary ovens circulate heat by the trolley that rotates inside whereas convection ovens use a powerful fan to distribute heat inside the baking chamber.

- For all rotary ovens they must contain a rotating trolley/rack. Most convection ovens do not contain the rotating trolley/rack although it can be added to make them rotary convection ovens.

- For a small production for a restaurant or bakery below 2,000 packets or pieces, the convection oven is very energy efficient whereas rotary oven is ideal for large industrial production of a single product e.g bread.

- Rotary ovens are very heavy and therefore difficult to keep changing temperatures that is why its ideal for large scale production of a single production e.g bread or cake. A convection oven changing temperatures is very fast and can bake a wide variety of products e.g in a restaurant or a cake shop.

What are the similarities between rotary oven and convection oven?

- Both have steam technology and therefore produce soft golden brown products. However, a bread proofer is still required for initial proofing.

- Both are efficient depending on scale of production. Rotary oven for very large scale and convection oven for small – middle scale production.

- Both can have a trolley/rack inside. It usually rotates in a rotary oven but its stationary in a convection oven. However, if the rack rotates in a convection oven, this oven is referred to as rotary convection oven.

Hybrid Rotary Ovens.

Rotary Oven Baking Bread.

Rotary Oven vs Convection Oven.

Rotary Oven Baking Scones.

Rotary Convection Oven.

| Number of trays | pcs | 32 |

| Tray size | cm | 60×80 |

| Power | kw | 3 |

| Voltage | v | 380/3N |

| Consumption | L/h | 7.5 |

| Temp. range | °C | 20°C – 300°C |

| Dimension | mm | 2200 x 1850 x 2350 |